كل الفئات

-

الماكينات

(29)

- قطاع المعادن (12)

- قطاع الأخشاب (15)

- قطاع الدعايا والاعلان (2)

-

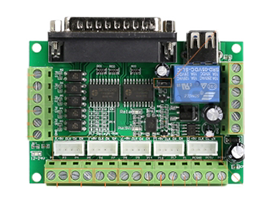

قطع غيار

(29)

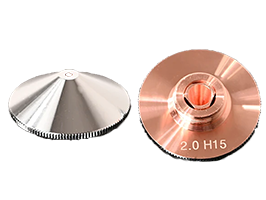

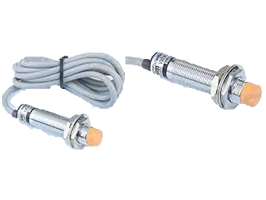

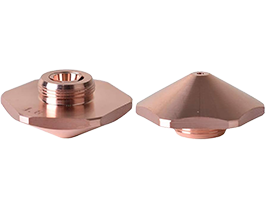

- فايبر ليزر (16)

- راوتر (12)

- ليزر co2 (1)

-

السعر